Expansion joint

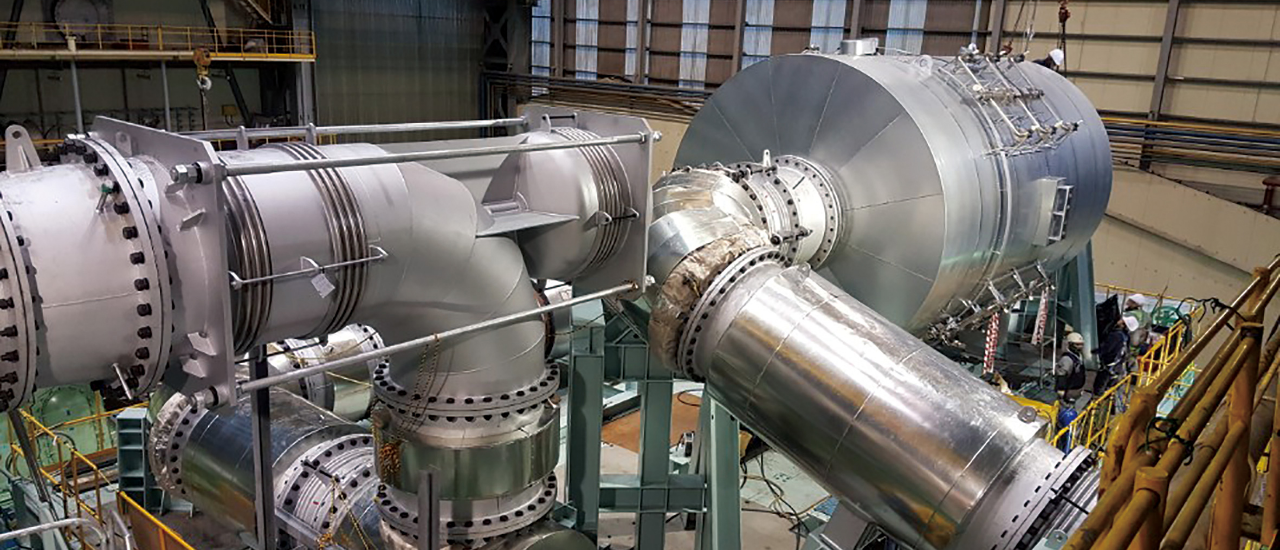

METAL EXPANISON JOINT

Major Functions / Features

Having the ability to compensate for axial movements

and with its simple and compact overall dimensions,

Expansion Joints are very widely used within a range of applications.

They are especially common in piping, examples of

which would include exhaust systems, ventilation and

flue gas systems, district heating, steam, oil and gas pipe systems.

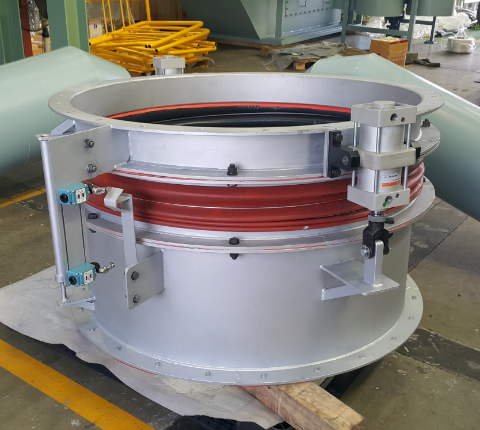

Non-Metal Expansion Joint

Major Functions / Features

Various materials are designed and constructed in accordance with the installation location and

conditions, and are highly flexible and have very little limitations in shape.

A flexible connected medium that absorbs all movement caused by temperature changes and

provides stability to the piping system. Non-metallic joints should be designed to be well

adapted to a variety of expansion capacities and temperature changes from time to time,

so that designers can reflect various ducts and pipe lines in the design to protect the equipment

from shrinkage, expansion, vibration, internal and external pressures, and to protect the entire

factory's industrial facilities. Manufactured from a wide range of non-metallic materials,

including synthetic rubber, fiber, insulation, and fluoride, depending on the design conditions.

Product Type

-

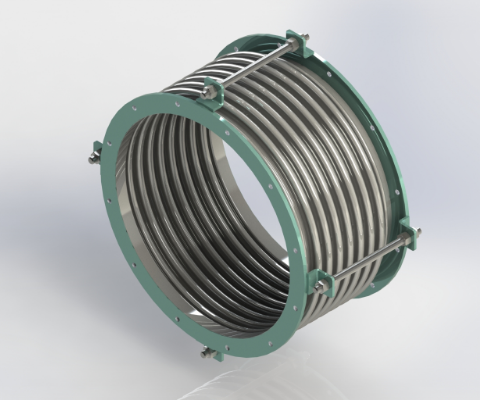

Single Unreinforced

Single Unreinforced

Single Unreinforced Metal Expansion Joints

-

Universal Unreinforced

Universal Unreinforced

Universal Unreinforced Metal Expansion Joint

-

Single Tied

Single Tied

Single Tied Metal Expansion Joint

-

Universal Tied

Universal Tied

Universal Tied Metal Expansion Joint

-

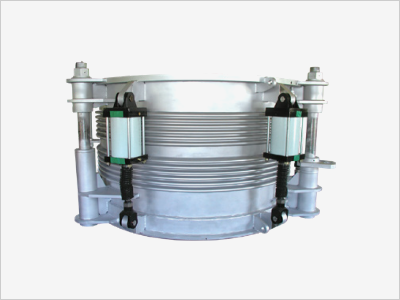

Cylinder Type Expansion Joint

-

Gimbal Type Expansion Joint

-

Reinforced Expansion Joint

-

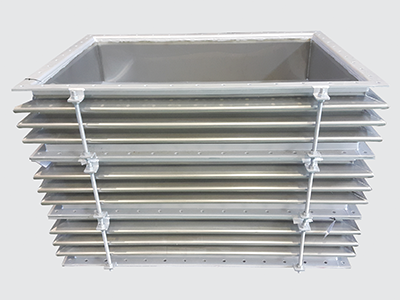

EXPANSION JOINT - RECTANGULAR

EXPANSION JOINT - RECTANGULAR

Miter Corner Type Expansion Joint

-

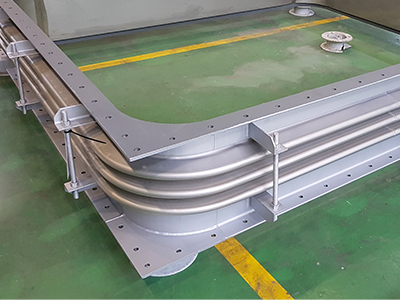

EXPANSION JOINT - RECTANGULAR

EXPANSION JOINT - RECTANGULAR

Round Corner Type Expansion Joint

-

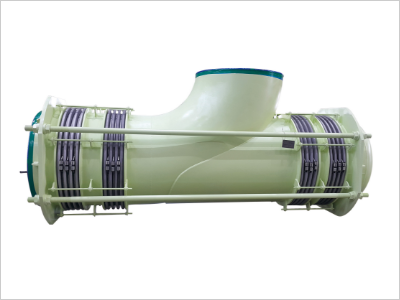

EXPANSION JOINT

EXPANSION JOINT

Pressure Balance Type

-

EXPANSION JOINT

EXPANSION JOINT

TEMA Bellows

-

Non-Metal Expansion Joint

Non-Metal Expansion Joint

Fabric